Who Uses Inkjet Printing?

Virtually every company that produces products also packages them for shipment and sale. Packaging includes the cans, bottles, jars, bags and/or shrink-wrap that contain the product itself, plus the boxes, crates, barrels, and pallets that bundle quantities of product for efficient shipment. Information printing on the packaging typically falls into two categories:

- Static message – the same for every package in a group

- Variable – all or part of the printed message changes for each package or production run.

What is Inkjet Printing?

Inkjet printing can be defined as propelling droplets of ink onto a substrate (the product that is being printed on) in a specific pattern without touching the object’s surface. This technology allows for various substrates to be printed on. These include porous, non-porous, smooth, textured, curved, concave, and more.

There are several advantages of inkjet printing over other technologies. Inkjet printing is non-contact. This means only the ink touches the products or packaging, and the product remains undamaged and stable. Both high speed and intermittent production can be used with inkjet printing making production lines efficient and accurate.

Types of Inkjet Printing

There are three main types of inkjet technologies: dot-matrix, hi-resolution (piezo), and continuous inkjet (CIJ). Continuous inkjet technology is when there is a continuous flow of ink from a pressurized reservoir. A deflection plate and an electrical field are used to control if and where the droplets of ink reach the substrate. Where the drop lands on the substrate and how far the droplet deflects is dependent on the strength of the charge on each droplet. As a result, the deflected drops create the image and the non-charged droplets are collected and recirculated.

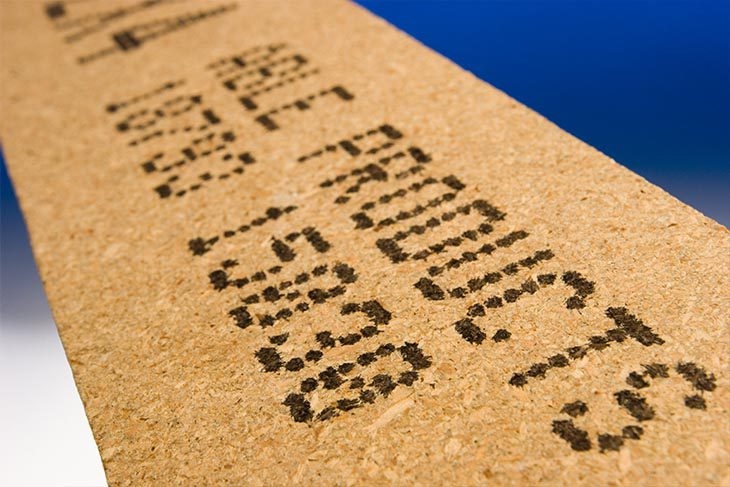

Dot-Matrix

Dot-Matrix (Drop-on-demand) is the other type of technology and it is when a drop of ink is only generated when a drop is needed. These drops are formed by a pressure pulse within the printhead. For instance, these codes can be seen on a number of porous and non-porous surfaces such as corrugated cases, metal, plastics, and more.

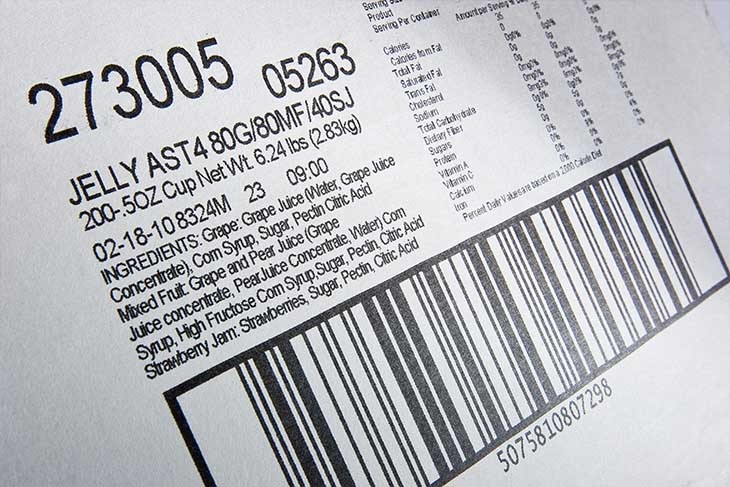

Hi-Resolution (Piezo)

Hi-resolution, or piezo printing, is technology that generates extremely small ink droplets by variably expanding, or pulsing, a piezoelectric crystal within a jet. A piezoelectric crystal undergoes distortion when an electric field is applied and this distortion is used to create a pressure pulse in the ink chamber, which causes a drop to be ejected from the nozzle. A main advantage of piezo technology is its ability to run a wide variety of fluids. Furthermore, this ensures good reliability and a long life for the printheads.

The Squid Ink CoPilot 500 printing system uses piezo printhead technology. The CoPilot 500 utilizes piezo technology by printing great looking barcodes and logos up to 2.8’’ in height per printhead. It also has the ability to run up to two printheads. Additionally, these logos and barcodes are printed on cases that run in a production line and can be seen in stores or when they are delivered straight to you.

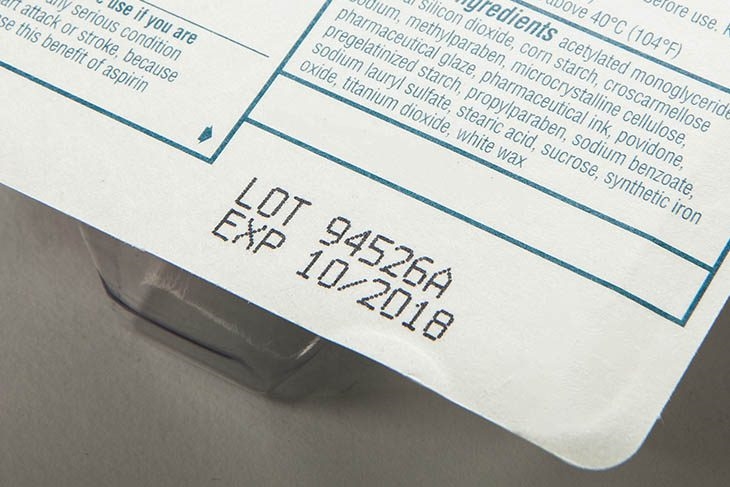

Continuous Inkjet (CIJ)

CIJ is the technology of choice for small character high speed printing. A reason that CIJ is a preferred method over others is its ability to use inks based on volatile solvents which allow for rapid drying. Moreover, many of these small characters codes are on items you would see every day. Date codes printed on the bottom of beer cans, expiration dates on a milk carton, and other every-day products.

To learn more about the inkjet printing technologies that Pyramid Packaging offers, visit our product pages. Contact us today using this form, or email us at [email protected].