Plastic pellets are heated up, melted and extruded to form the plastic film. The film can be clear, opaque or high gloss and made from polypropylene, and polyethylene. Some packaging films offer high-barrier properties which makes them a good fit for food packaging.

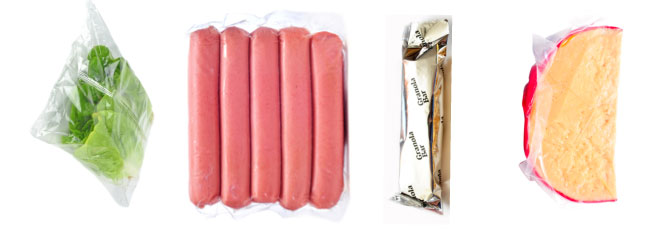

They provide protective properties for food items requiring restrictive visibility and will also increase the product’s shelf-life, and freshness.

Oxygen transfer rate (OTR) is used to measure the amount of oxygen that passes through a film. A good rule of thumb is this: The lower the number, the better the film barrier.

Additional barrier properties include UV protection, odor prevention, moisture and gas barriers. Deciding on the barrier film for your packaging application can be a complicated process.

There are many variables to consider in order to best preserve your packaged product.

Below are a list of the most common type of barrier films used for food packaging.

Foil (aluminum) backings

These offer the best best barrier protection with an OTR of 0. Foil is often used in candy wrappers, as well as preserving chocolate.

EVOH (ethylene vinyl alcohol)

These barrier films have a OTR at .6 cc EVOH barriers are often used to package items such as meat, fish & poultry related products.

MPET

When OPP/BOPP films are laminated with metal foil (MET) it will increase the film’s oxygen & water barrier & block out UV rays. Additionally, because of the film’s stiffness, it is used as a wrap for hard candies, chocolates & is resistant to heat and moisture.

KPET

This is a soft saran coated PET film with good transparency. It is used as a substrate to laminate with other films. KPET has excellent gas, moisture and vapor properties making suitable for packaging of dry goods and protecting fragrant related items.

PET (polyester)

This is very good oxygen barrier, heat resistant & strong film with good durability. PET film is an excellent laminating substrate for stand-up pouches. Therefore, when PET films are laminated with metal foil it will increase the film’s oxygen — water barrier & block out UV rays.

Metallized films for flexible packaging are essential when the product requires extra protection to ensure a longer shelf life. MET PET provides protective properties for food items requiring restricted visibility.

Nylon barrier films

These films have a high melting point and are used for cooking applications such as boiling, microwaving & baking. As a result, it has very good clarity, moisture barriers & is considered a very strong film.

Polypropylene barrier films

This material is soft, clear glossy film with good moisture barriers and high oxygen transfer rates. It is often used for plastic food bags.

LLDPE barrier films

This type of films are inexpensive and have good clarity. It is used to package fresh, produce, frozen foods & baked goods. Because of its high OTR of 2500 cc, it work well when the package requires oxygen.

About Pyramid Packaging

Est. in 1968, Pyramid Packaging is a value-added supplier of flexible packaging films, equipment & services. We also create value by working with clients who need help in selecting and customizing their packaging films. Pyramid Packaging can customize your plastic packaging films & barriers according to your blend, size & graphic design. Call us at 847-272-3400 or contact us here.