Remember when grocery store items mainly consisted of rigid packaging such paperboard boxes, glass and plastics? Today many of these rigid packaging products has been repackaged with flexible plastic pouches. Items like meats/poultry, snacks, drinks, dry foods condiments, detergents and even alcohol are packaged in pouches. Because of their advantages, flexible plastic pouches are the fastest-growing type of packaging.

Flexible pouches are lightweight, used for a variety of applications, customizable, printable, and reusable. They also come with re-closable zippers. This makes it unnecessary to use scissors or knives to open the pouch and will keep products fresh after its initial use. With gusseted bags, the bottom folds out when filled so it can stand up on its own without tipping over.

These pouches are environmentally friendly since they use few resources to produce them resulting in a smaller carbon foot print and waste. Unlike rigid packaging, pouches take up less room on a store shelf, and are less bulky so they are easier to transport. Since they are available with oxygen barriers, they are also used for liquids like milk, wines, and juices.

There are additional benefits to using flexible pouches for your application, including:

- Extended shelf life

- Retains freshness of product

- With different types of layers, adhesives and sealing, it is customizable to your needs

- Easy to open

- Easily transportable

Additionally, they can be made out of a variety of packaging films, including: Low-density polyethylene (LDPE), Linear low-density polyethylene (LLDPE) and High-density polyethylene (HDPE).

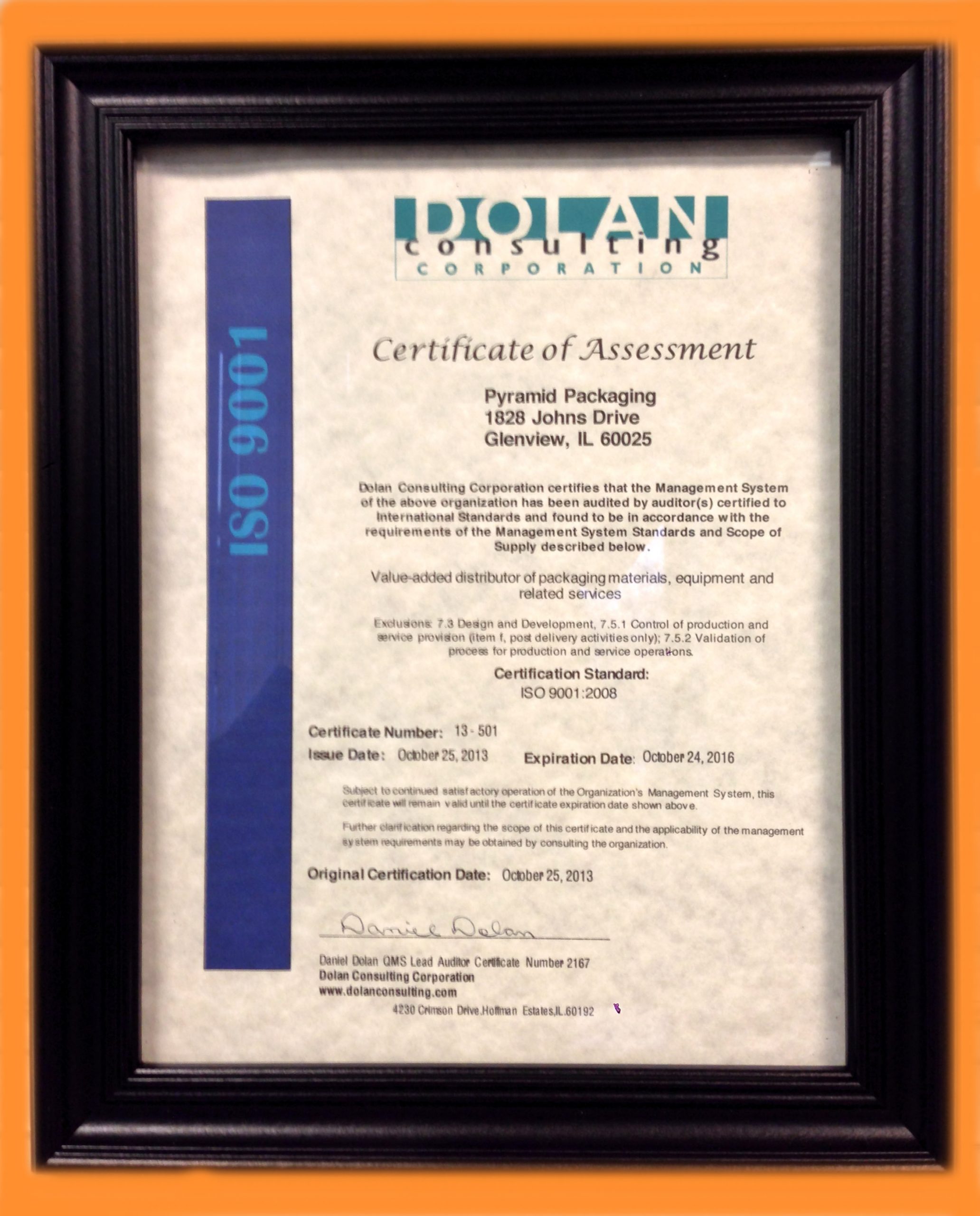

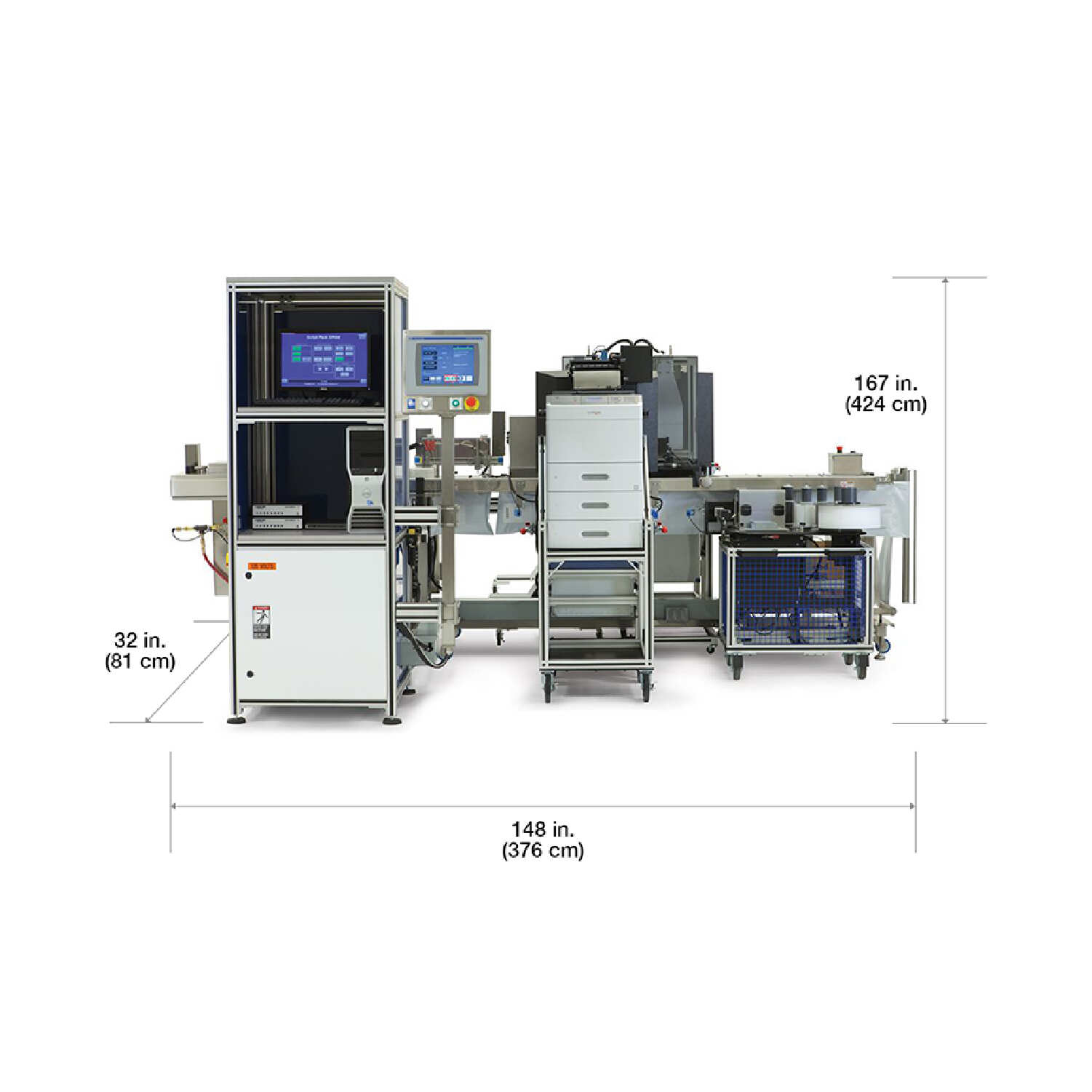

Pyramid Packaging is a value added reseller of flexible pouches and bagging equipment. We offer a variety of flexible pouch sizes, and colors. For more information call 847-272-3400 or click here to email us.