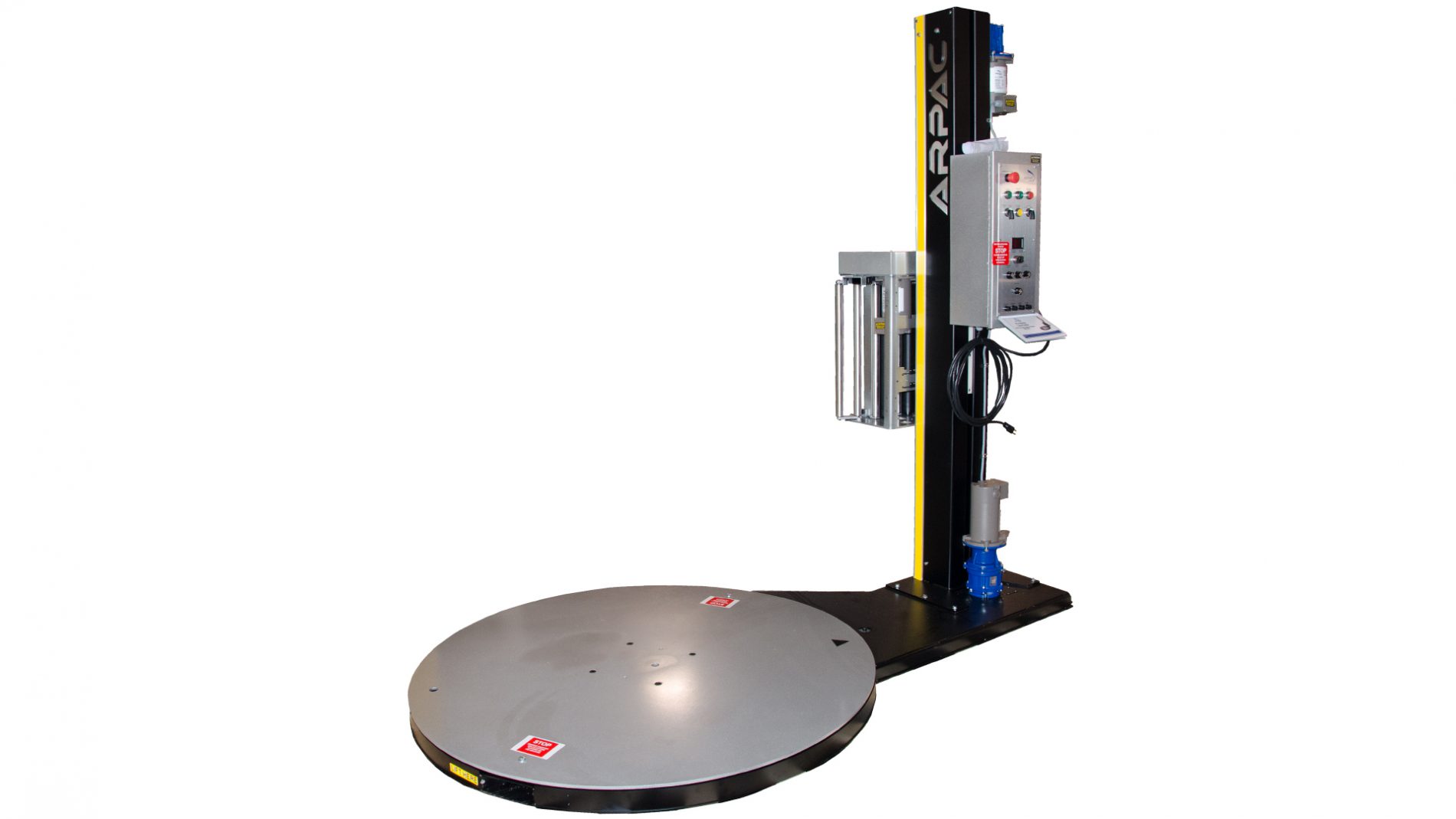

The new ARPAC Pro-Series enjoys the reputation of being one of the most cost-effective semi-automatic machines on the market today. A new ergonomic, sturdy design with chains enclosed in the tower frame ensures safer operation. Standard features include: illuminated adjustable (0-7) LED top & bottom wrap counters, top overwrap control, anti-static film rollers, cycle pause, variable speed controls for both turntable and carriage, upgraded photo-eye to see most dark loads, plus EZ-Load Powered Pre-Stretch, maximizing stretch film usage.

The ARPAC Pro-Series is often purchased with the Wrap-N-Weigh feature that combines wrapping and weighing operations. A precision scale and digital controls are integrated into the machine, bringing more excellent economy and efficiency to any wrapping operation requiring weighing.

This 4,000 lb. capacity system is available with a high-profile turntable for forklift loading or a low-profile turntable for pallet-jack loading.

The Pro-Series can be customized to suit your material handling requirements with extended towers for taller loads and split frames for odd-sized larger loads.

The Pro-Series is part of a robust line of stretch wrapping equipment designed to maximize stretch film usage while ensuring the very best load unitization. All equipment is constructed with heavy-duty reinforced structural steel and finished with non-corrosive Steel-It paint to guarantee years of reliable wrapping.

The Pro-Series is manufactured in the USA.

Features:

- Heavy-duty, welded steel construction (no plastic panels) designed for long life

- Variable turntable speed using 1/2 hp, 90 Vdc motor with ANSI 50 chain drive system, no rubber belts

- Up to 12 RPM rotating table can deliver 25–40 loads per hour

- Long-range photo eye for automatic load height sensing

- Automatic top film overwrap control feature (TOC)

- Adjustable top and bottom illuminated LED wrap counters

- Cycle pause feature

- Electronic film tension adjustment control on the control panel

- Manual jog control for turntable

- Eco-friendly, durable, powder coating

- Film Delivery System

- EZ-Load film pre-stretch dispenser for 20″ film rolls

- Dual anti-static film rollers with manufacturer’s lifetime warranty

- Film pre-stretch capability from 150 to 300% stretch (200% standard)

- Variable carriage speeds up to 21 feet per minute

- 1/2 hp, 90 Vdc motor with ANSI 40 chain lift drive

- Dancer bar variable-corner compensation

- Electronic film tension adjustment control

- Allen-Bradley power, control, and safety components

- Allen-Bradley MicroLogix PLC

- UL/CSA approved components

Technical Specs

Speed:

- Turntable rotation speed Up to 12 RPM

- Variable carriage speed Up to 21 FPM

- Loads wrapped per hour 25 to 40

Power Requirements: 120 VAC, 1 Ph, 60 Hz, 10 A

Compressed Air Requirements: None

Height Range:

- LP 81” max load height (117″ with tower Extension option)

- HP 74” max load height (110″ with tower Extension option)

Film Roll Diameter: 20”

Other Film Specifications: Film pre-stretch capability from 150% to 300% stretch factor (200% standard)