May 2014 — Pyramid Packaging has moved to 2901 Shermer Road Northbrook, IL 60062. Our new phone number is 847-272-3400. To contact us, reach out here.

The new office is located only a couple of miles from our old location. There were a number of reasons to move. These include: a larger warehouse, showroom and office space. Therefore, these became more pressing due to the growth of our business and the flexible packaging supplies market.

After 11 years of growth at our previous location on Johns Drive in Glenview, we literally ran out space. Our new larger office allows us to inventory a wider selection packaging films, bags and equipment.

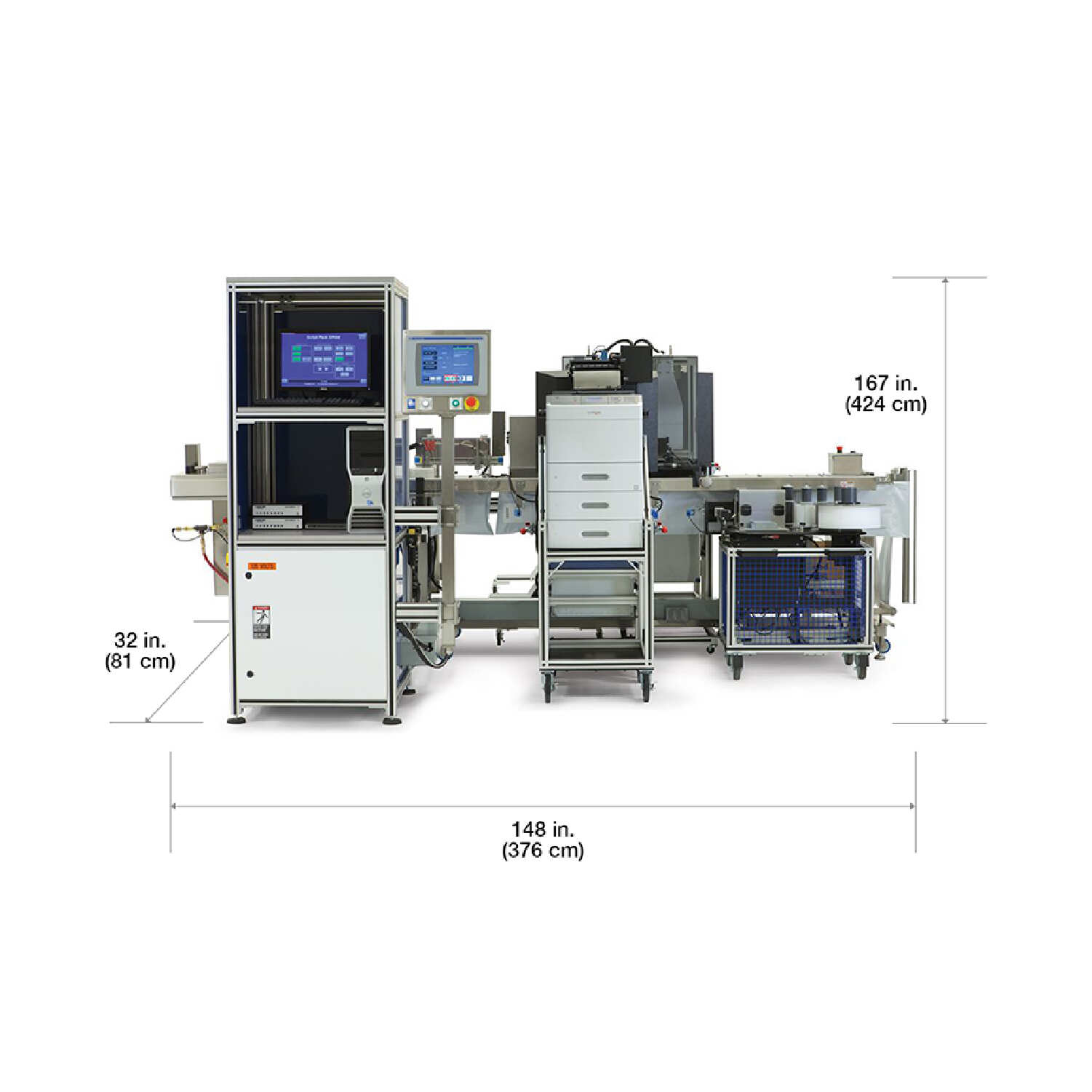

We will also have a machine showroom which features the latest packaging equipment (under power) from our leading suppliers like ARPAC, Autobag, Loveshaw and Starview.

The move to our new location is an exciting time for all of our employees, particularly because they are working hard to make the transition seamless for our customers.

Since we own our new building, we are able to give it a personal touch. We customized it with LED lighting, office décor and outdoor landscape and also upgraded our in-house technology.

About Pyramid Packaging

Established in 1968, Pyramid Packaging is a value-added reseller of flexible packaging machinery, supplies, and services. We offer the latest in B2B packaging solutions.