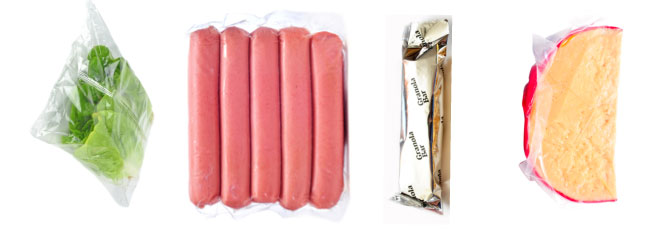

Understanding the different types of food packaging films and their applications can be confusing. With names like Low Density Polyethylene (LDPE), Cast Polypropylene (CPP), Metallized Oriented Polypropylene (MET-OPP) or Polyethylene Terephthalate (PET), one might think you need to be a chemistry major.

Plastic film for packaging offers several advantages over their rigid counterparts. Here are some reasons as to why. First, films are lightweight. Next, they are easy to print on. Third, they have excellent barrier properties to help it stay fresh. Finally, certain kinds are recyclable or reusable.

We create value by helping our customers select the best film for their packaging needs. Pyramid Packaging also provides resources like the slide share presentation below to help you get a head start on deciding on what type of film is best for your application, no matter what section of the grocery store or weekend farmer’s market it can be found in.

Read our “Understanding Food Films” to better understand the types of films /properties and the types of food they package.

Reach out to Pyramid Packaging today to inquire about our different film offerings by filling out this form, or by emailing us at [email protected].