Autobag’s DATA Count U-162 Counter integrated with the Autobagå¨ 500㢠bagger is specifically engineered to fully automate the high-speed counting and packaging of bulk small products. It is a compact, flexible and cost effective system designed with advanced counting technology from DATA Technologies and innovative product engineering from Automated Packaging Systems. Capable of counting […]

Flexible Packaging Films

Flexible packaging films are used to package, preserve and protect a variety of items such as fresh foods, dry goods, pharmaceutical and consumer products. The films are used to make poly bags/pouches, stretch wrap, shrink wrap, bubble wrap and void fill supplies. Flexible packaging supplies provide several advantages because they are lightweight resulting in lower shipping […]

Food Metal Detectors

Food metal detectors are used for consumer protection. The consequences for a food related packaging company that is not using metal detectors can include lawsuits, recalls and hurt their brand image. Parts of the food processing and packaging equipment like nuts, bolts or metal shavings can possibly fall off an accidentally be packaged with the […]

Textile Packaging Equipment

Autobag’s new Ergocon Textile Packaging System is engineered specifically for high speed packaging of industrial laundered applications and textile rental services. The laundry packaging system uses an automatic feeder, fully integrated with the Autobagå¨ AB 255㢠wide bagger, to inspect and package up to 7,000 towels per hour. The inspection and packaging operation begins by […]

Self Propelled Stretch Wrapper

Highlight’s self propelled Fantom stretch wrappers give you the freedom to wrap loads anywhere in your facility without sacrificing consistency and film savings. The semi-automatic controls make wrapping varying sized loads simple and easy. The self-propelled load tracking design means that products of any weight, length, or width can be wrapped an eliminates the need […]

PackExpo

The Pack Expo show took place Nov. 6-9 in Chicago. The show gives us an opportunity to meet with many of our suppliers since most exhibit at the show. It also gives our packaging engineers the chance to see the latest in packaging equipment, films and supplies that may benefit our customers. Pack Expo is […]

Automated Packaging System – PackExpo 2016

If you plan on attending PackExpo 2016 Chicago be sure to visit the Automated Packaging System’s exhibit located in McCormick Place’s South Hall #2438. Pyramid Packaging has been representing Autobag’s line of packaging supplies and equipment in the Chicagland area for over 50 years and was recently selected as their Distributor of the Year. Free […]

Why Use Anti-Static Shielding Bags

Anti-static shielding bags are used to store, transport and protect electronic components and printed circuitry boards. The bags will protect electronic items from damage when electrostatic discharge occurs. Static electricity occurs more often when there are low amounts of moisture in the air. Anti-static bags have a thin microscopic layer of water molecules at the […]

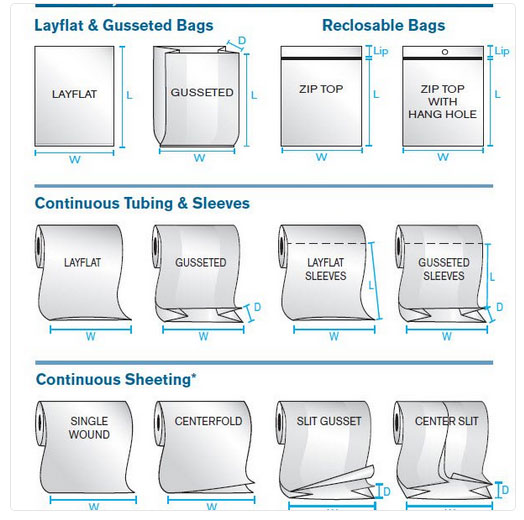

Choosing the Right Poly Bag

Choosing the right poly bag (film) for your packaging application can be a confusing process. If you’re not familiar with packaging films, you may think they are basically all the same but nothing could further from the truth. Poly bags come in different styles, materials, thicknesses, blends, barrier properties and available in loose pack and […]

Something Smells Good

Oxygen transfer rate (OTR) allows a flexible packaging film to either reduce or allow the smell of an item to penetrate the film at a certain temperature. OTR is the amount of oxygen that penetrates a given area in one day. However the relative humidity can affect barrier properties of certain films. Plastic films with a […]

Egg & Light Bulb Toss

The Adventures of EggMan & Light Bulb Boy […]

Amazon FBA Packaging Supplies

Many businesses are now selling their products on Amazon and using their FBA (fulfillment by Amazon) to send it directly to the customer. Amazon FBA does have requirements on how the items need to be packed. If they are not packed properly, it can create delays in the items getting into Amazon’s inventory. Using the […]

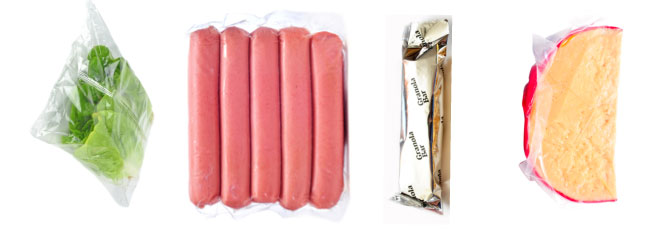

Barrier Films for Food Packaging

Plastic pellets are heated up, melted and extruded to form the plastic film. The film can be clear, opaque or high gloss and made from polypropylene, and polyethylene. Some packaging films offer high-barrier properties which makes them a good fit for food packaging. They provide protective properties for food items requiring restrictive visibility and […]

Barrier Films for Food Packaging

Barrier Films for Food Packaging from Pyramid Packaging Inc. […]

Deciding on Packaging Films

Deciding on Packaging Films from Pyramid Packaging Inc. […]