Block-brace air tube packaging is a technique that fills or surrounds the void fill areas of a packaged product. This secures the items and reduces the chances of it getting damage during shipping and the wider transportation process.

Automated Packaging Systems AirPouch FastWrap air tubes protective packaging is more cost effective when compared to other types of block and brace materials, such as Styrofoam peanuts, foam-in-place, or molded pulp inserts.

The on-demand air tubes are lightweight, and reusable. The block-brace air tube are dust free and durable enough to provide excellent product protection in a minimal space.

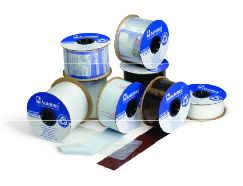

AirPouch FastWrap tubes come in a compact box that generates more than 1,380 linear feet of protective packaging. The tubes can be inflated when needed at speeds up to 65 feet per minute. Compact and convenient, the all-electric design and small footprint of the AirPouch FastWrap is ideal as a stand-alone system or combined with a variety of equipment accessories for any size pack station.

AirPouch FastWrap cushioning bubbles feature our patented, channel-filled honeycomb design, which

allows multi-direction wrapping and improved product protection. FastWrap block-and-brace tubes feature the patented EZ-Tear Perforations between each tube, making them easier to separate and reducing material waste.

Pyramid Packaging is a supplier of Autobag AirPouch FastWrap. For more information click here or call us at 847-272-3400.